We appreciate your interest and will get back to you as soon as possible to prepare a quote. In the meantime, feel free to discover more products on our website.

Product information

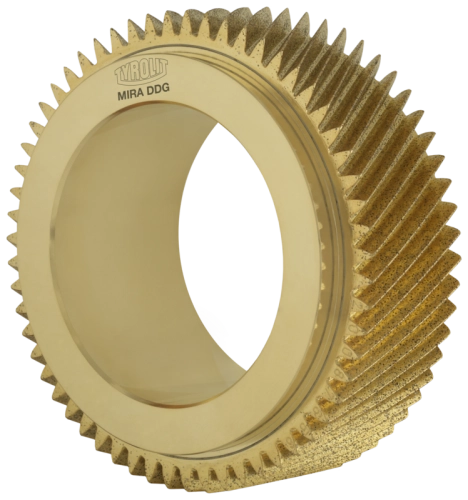

Description

TYROLIT's MIRA DDG has made the company into a market and technology leader in the field of diamond dressing gear production. Honing rings are trued and sharpened during the dressing process. Thanks to their high level of reproducibility and cutting ability, MIRA DDG dressing gears guarantee optimum dressing results, the best possible gearing and surface quality as well as long tool lifetime.

Features

-

Cutting ability:

The process for producing MIRA DDG dressing gears developed by TYROLIT guarantees aggressive, reproducible tools.

-

Accuracy:

The use of state-of-the-art measuring equipment in the various phases of production guarantees products of the highest precision.

-

Replating option:

MIRA DDG diamond dressing gears can be reused several times by applying a new diamond layer.

-

Gear cutting expertise:

TYROLIT specialists are responsible for design and production to meet the most stringent gearing requirements, including topological modifications.

-

System solution:

The designs and specifications for MIRA DDG diamond dressing gears are perfectly tailored for use with MIRA REX honing rings.

Abrasive Grain

- Diamond (D)

Bond Classification

Galvanic

Recommendations

Explore related products

MIRA DDS

Diamond-dressing tools for dressing of gear grinding wheels for continous generating gear grindingGear honing

MIRA REX COMP

Vitrified bonded honing wheels for tooth flank honing in composite designGear honing